7 Steps to 5 Why

John is the young Production Manager at a food manufacturing plant. John came to work this morning optimistic that today was going to be a great day. He is feeling pulled down though as he and his team are fighting a downtime issue. The filler on his highest priority line is down for another bearing failure. Fred, the seasoned Plant Manager has seen this before. He is putting on the heat: “What’s wrong, John, didn’t this bearing go out last week too?”John replies, “Yes, this is the same bearing. Everyone thought that it was just too old and was wore out. I guess we were wrong.”

Fred wants John and his team to learn from the experience and is not interested in placing blame: “OK, John. Let’s see what we can learn from this breakdown. What do you think we should do differently this time? We don’t want this bearing to burn us 3 times, do we?”

“No, we certainly don’t, ” says John. ”I’ll lead a 5 Why to make sure we get to the root cause this time….”

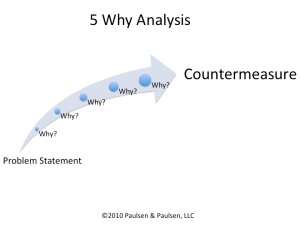

John knows that the 5 Why Root Cause Analysis is a great tool. The 5 Why will help you get to the root cause and implement effective countermeasures when done properly.

There are 7 Steps to an effective 5 Why:

- Problem Selection: There are plenty of issues out there. Select one that you can focus on. Use the Pareto Principle to make sure you get a good bang for the buck.

- Problem Statement: Define the problem. Be specific. Keep the scope small and realistic.

- Ask Why 5 Times & Select Countermeasures: Start with the problem statement. Ask why it happened. Ask why until you have found the root cause. Asking why 5 times often gets to the root cause. Discuss and select the countermeasures that will ensure you don’t have this problem again. Addressing the true root causes prevents or at least minimizes the problem.

- Implement Countermeasures: Communicate the changes to everyone who needs to know. One Point Lessons are often good for this purpose. Don’t forget the night-shifts and other departments.

- Analyze Effectiveness: Review the results of the new procedures. Modify the countermeasures if needed. You may even need to try something completely different if the countermeasures are not effective. In this case, you should also ask yourself if you really got to the root cause.

- Standardize: Update your SOP’s to reflect the new procedures. Update training plans for new operators. Ensure that everyone who needs to know is in the loop. Ask yourself if there are other areas to apply the new knowledge. You may have another production line with the same equipment that could use the same improvement.

- Check & Control: Implement systems to insure the new procedures are followed and are effective. Follow up.

What about you and your team? Do you have repeat issues that you need to resolve? The 5 Why Root Cause Analysis (RCA) will help you find and address the root causes.

No comments:

Post a Comment